- Beijing Janyhong Ntsuas Cov Khoom Siv Hauv Machanical Corp Ltd.

- bjmmec@yeah.net

- +86 15201347740 / + 86 13121182715

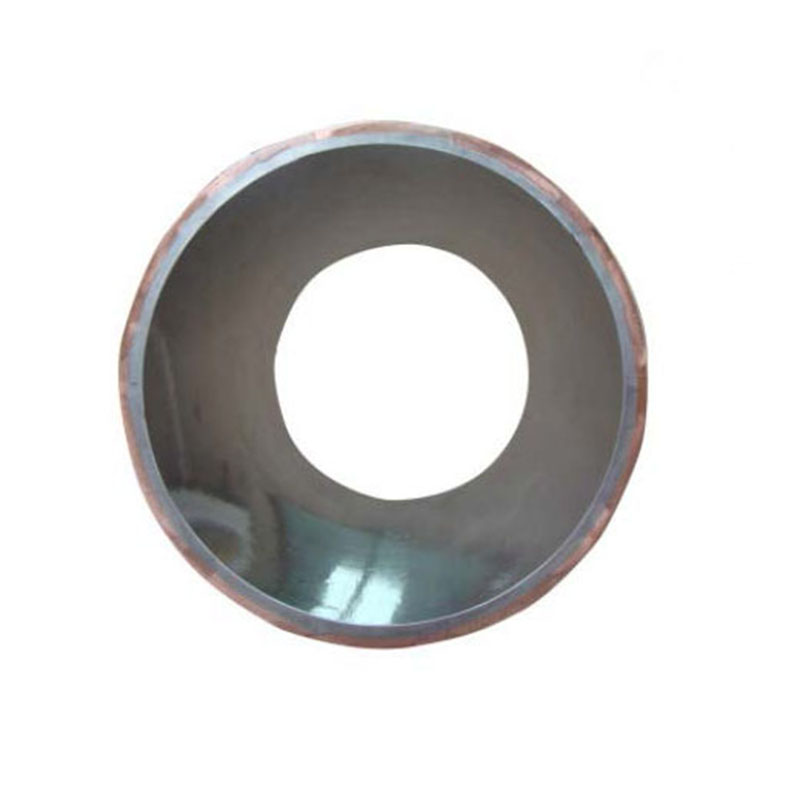

Steel melting cog ccm spare chaw tsim tshuaj paus Mould leeg

Khoom Taw Qhia

✬ maj mam solidifying lub puab tsaig hlau mus rau hauv lub plhaub ntawm qhov yuav tsum muaj loj thiab cov qauv;

✬ los ntawm kev co ntawm cov pwm kom tshem lub plhaub los ntawm cov pwm uas tsis tau rub tawm thiab tawg tawm hlau;

✬ Los ntawm kho cov tsis sib xws ntawm cov pwm, cov kab xev tsis meej tsis muaj qhov tsis xws luag xws li stripping, kev thab plaub thiab tawg;

✬ Ua kom ntseeg tau cov khaub ncaws zoo thiab ruaj khov ntawm lub plhaub.

Cov lus qhia

Cov khoom siv: CUDHP, CUAN, CUCRZR

✬ txheej txheej: CR, tshee n

Round puag ncig ntawm φ100mm rau φ1000mm

| HLOOV LACHET CRYSTALLIALLizer tooj liab raj sporification | ||

| Rooj plaub | Casting tshuab vojvoog | Khoom ntev |

| φ90 | R = 3000-500 | L = 812-850 |

| Daab100 | R = 3000-6000 | L = 812-850 |

| ®105 | R = 5000-6000 | L = 812-900 |

| φ110 | R = 6000 | L = 812-900 |

| Play120 | R = 5250-8000 | L = 812-900 |

| DaC130 | R = 5250-8000 | L = 812-900 |

| Play140 | R = 5250-8000 | L = 812-900 |

| OL150 | R = 5250-8000 | L = 812-900 |

| Play160 | R = 6000-9000 | L = 812-900 |

| Play180 | R = 6000-10000 | L = 812-900 |

| φ190 | R = 6000-10000 | L = 812-900 |

| Daab200 | R = 6000-10000 | L = 812-900 |

| φφ10 | R = 6000-10000 | L = 812-900 |

| Play | R = 6000-10000 | L = 812-900 |

| Dig 230 | R = 6000-10000 | L = 812-900 |

| Play280 | R = 6000-10000 | L = 812-900 |

| φ310 | R = 6000-15000 | L = 812-900 |

| φ320 | R = 6000-15000 | L = 812-900 |

| φ330 | R = 6000-15000 | L = 812-900 |

| φ340 | R = 6000-15000 | L = 812-900 |

| φ350 | R = 6000-15000 | L = 812-900 |

| φ400 | R = 6000-15000 | L = 812-900 |

| φ450 | R = 6000-15000 | L = 812-900 |

| ®500 | R = 6000-15000 | L = 812-900 |

Tsom rau kev tsim qauv, kev tsim khoom thiab kev pabcuam ntawm cov khoom siv metallurgical rau 30 xyoo.

Txhua tus neeg siv khoom-centric daws tau koj cov kev xav tau tam sim hauv thawj thawj zaug tau khiav tawm ntawm cov neeg siv khoom.

Yog tias qhov teeb meem tau tsim los ntawm peb, peb yuav tsum daws nws.thiab yog tias cov teeb meem tsis ua los ntawm peb, peb yuav muab koj kev koom tes los daws nws.

Cov pab pawg sab saum toj, cov thev naus laus zis tshuab siab dua tshiab thiab kev paub tseeb kev lees paub zoo los muab koj cov kev pab tau zoo thiab kev pabcuam zoo.