- Beijing Jinyehong Metallurgical Machinery Equipment Corp.

- bjmmec@yeah.net

- +86 15201347740 / +86 13121182715

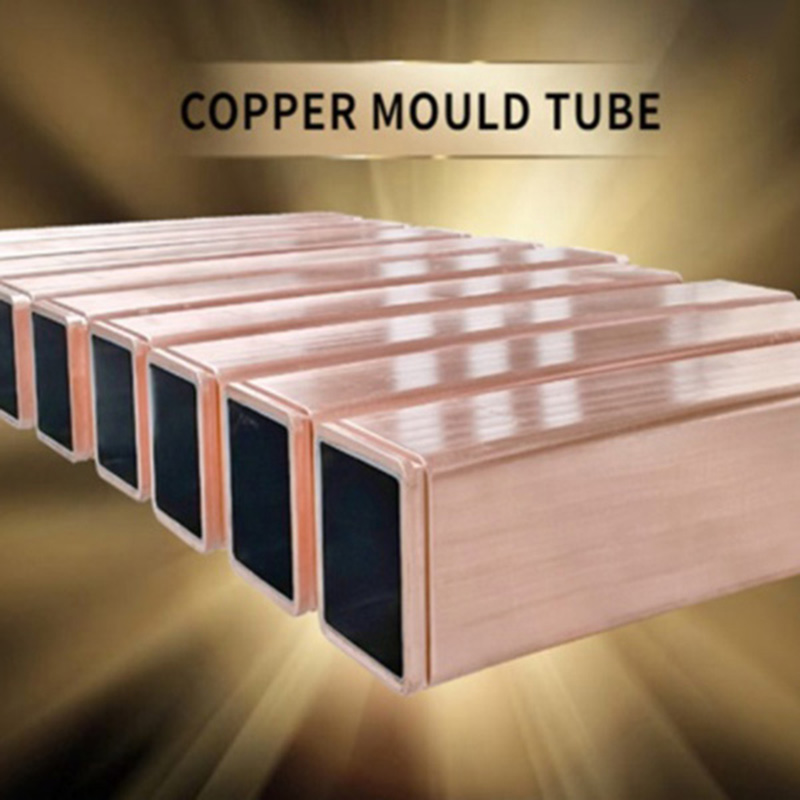

Composite Copper Pwm Tube

Taw qhia ntawm Composite Plating

Nws hais txog ntau txheej txheej.xws li cov ntaub ntawv ntawm 2 hom yuav tsum tau coated mus rau lub raj tooj liab nyob rau hauv ib ntus.Thawj txheej ntawm nickel-cobalt alloy yog yuav tsum tau coated mus rau lub raj tooj liab li nruab nrab txheej, raws li qhov thib ob txheej ntawm Chrome yuav tsum tau ua raws li anti-wearPlating Technics:

Composite plating yog Hard Chrome txheej, muaj ob hom hu ua npib tsib xee-cobalt alloy, uas ib tug yog amido-sulfonic acid system nrog nickel aminosulfonate & cobalt aminosulfonate ua raw cov ntaub ntawv whereas lwm yam yog sulfuric acid system nrog nickel sulphate & npib tsib xee. cobalt ua raw khoom.Tus qub yog superior rau yav tom ntej nyob rau hauv technics rau npib tsib xee sulphate nrog kev nyuaj siab yuav poob tawm ntawm txheej.Los ntawm qhov sib txawv, amido-sulfonic acid system nrog qis kev ntxhov siab ntawm kev ruaj ntseg zoo.

Qhov zoo

Nickel-Cobalt txheej raws li cov txheej txheem hloov mus ua kom lub neej dhau ntawm cov kua hlau, hauv lwm lo lus, vim tias qhov nthuav dav ntawm tooj liab thiab chrome yog sib txawv kiag li, nyob rau hauv cov txheej txheem ntawm cua sov thiab cua txias, expansion shrinkage yuav ua rau kom poob tawm. los ntawm txheej.Yog li ntawd, ua ntej chrome txheej, cov txheej txheem hloov pauv ntawm nickel-cobalt ua haujlwm tsis pub dawb los ntawm cov teeb meem tso tawm, uas ua rau txo qis kev cuam tshuam rau txheej txheej hauv cov txheej txheem cua sov thiab txias ua rau lub neej dhau mus.

Kub: 20 ℃ (1E-6 / K lossis 1E-6 / ℃)

| Hlau | Expansion Factor |

| Tooj | 6.20 ib |

| Nickel | 13.0 Nws |

| Chrome | 17.5 Nws |

Hla lub neej ntawm kua hlau: 8,000MT (Chrome Plating)

Hla lub neej ntawm kua hlau: 10,000MT (Composite Plating)

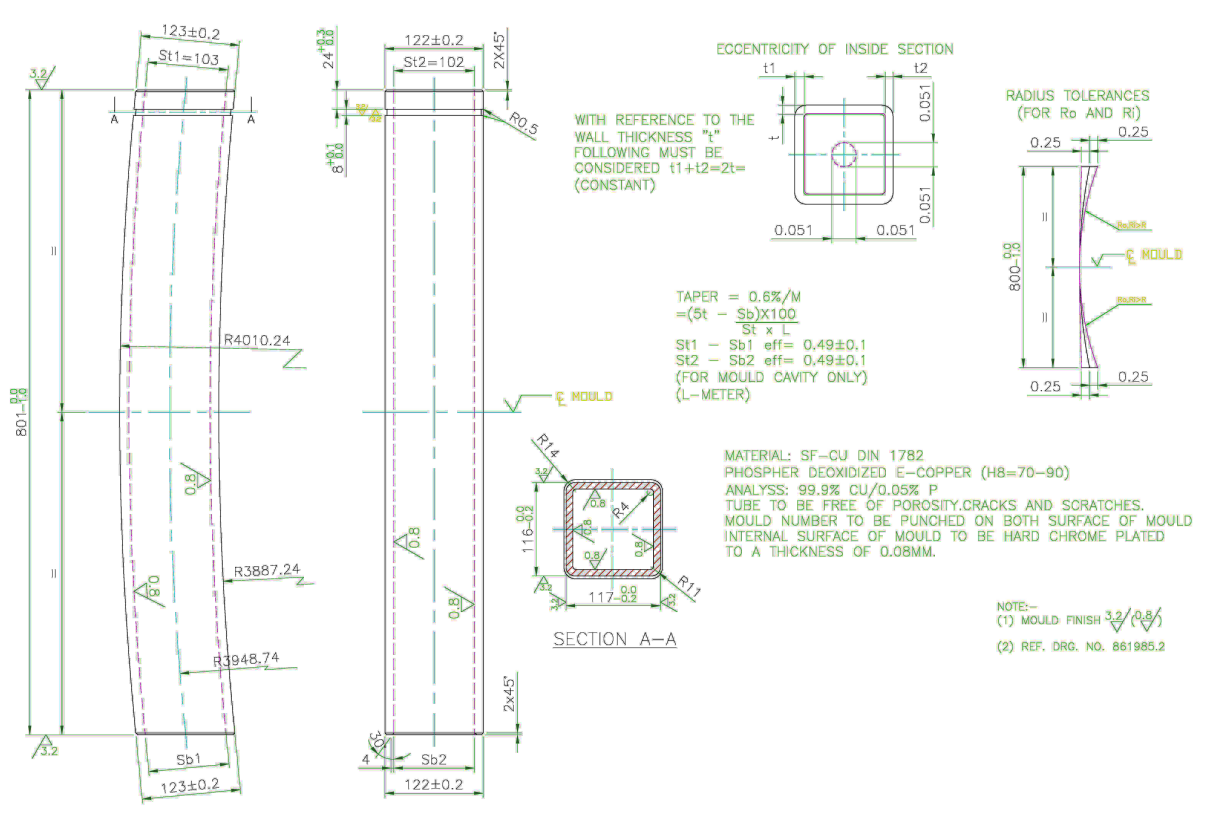

tooj liab pwm raj rau nruam casting tshuab muaj cov yam ntxwv zoo raws li hauv qab no:

1. Kev puas tsuaj zoo heev;

2. tiv taus qhov kub thiab txias;

3. Zoo corrosion kuj;

4. Muaj zog thiab siab hardness;

5.Zoo tshav kub dissipation