- Beijing Janyhong Ntsuas Cov Khoom Siv Hauv Machanical Corp Ltd.

- bjmmec@yeah.net

- +86 15201347740 / + 86 13121182715

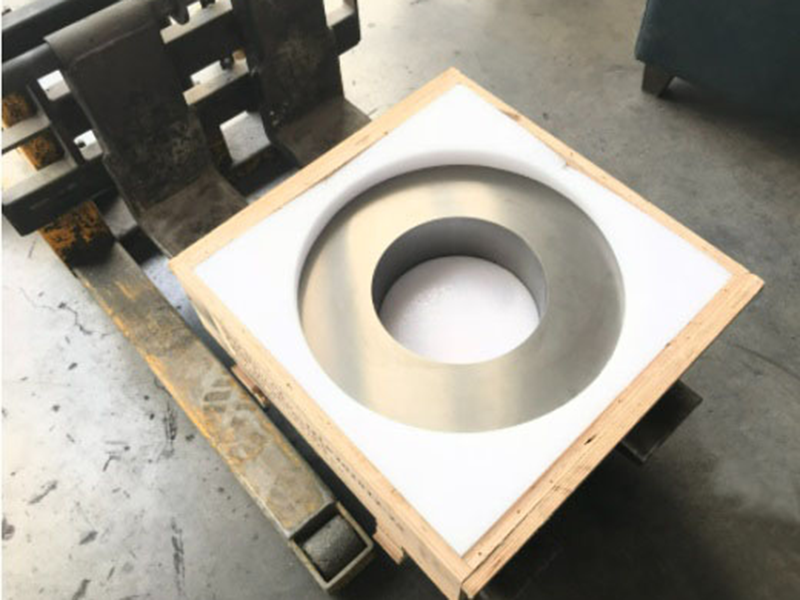

TC DOV Cov khoom siv rau cov hlau yob tshuab

Khoom Taw Qhia

cemented carbide yob ib ncig (tseem hu ua tungsten carbide dov nplhaib) muaj cov cuab yeej thermal zoo. Piv nrog rau lwm cov ntaub ntawv, nws yog qhov zoo dua nyob rau hauv cov nqe lus ntawm tshav kub-ua hauj, ris-resistance, hnav-ua hauj lwm thiab lub zog. Dab tsi yog ntau ntxiv, nws hardness txo me ntsis nyob rau hauv kev mob ntawm qhov kub. Yog li, cov cemented carbide yob ib ncig yog tsim nrog kev loj hlob hlau rod mill.with txoj kev txhim kho ntawm cov hlau loj, bar thiab deformed steel bar.

Raws li cov khoom siv rau peb cov khoom lag luam, muaj ob hom lus li WC-CO thiab WC-Co-Ni-Cr uas muaj cov khoom siv zoo li qub. Dabtsi yog khoov zog thiab tej yam nyuaj ncav cuag 2200 mpa thiab (4-) x106j / m Nyob rau tam sim no, cov pob tiav tau feem ntau muaj ntawm 8- 10 sawv ntsug. Vim tias qhov loj me ntawm pob txha lov ntawm lub ntsej muag ntawm lub ntsej muag, lub dab tshos ntawm sab xub ntiag sawv ntawm cov pob zeb tiav thiab muaj zog cuam tshuam. Yog li, lub siab tawv thiab zoo thermal nkees ua tsis tau yog thawj qhov kev hnav khaub ncaws thiab cuam tshuam rau cov khaub ncaws uas tsis tshua muaj zog. rings. Tam sim no, lub pob zeb tiav feem ntau tsim ntawm 8- 10 sawv. Yog li, lub siab tawv thiab zoo thermal nkees tsis kam yog thawj yam, uas yog ua ntej hnav-ua kom tsis kam. Peb yuav tsum them nyiaj ntau rau cov kev hnav uas tsis kam thiab thermal nkees ua kom tsis kam ntawm yob ib ncig.

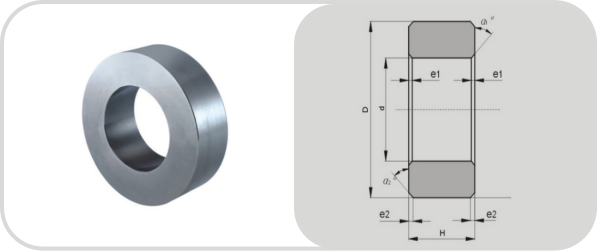

Nqe lus piav qhia ntawm TC Ntiv nplhaib

| Rang ntawm od (hli) | Rang ntawm ld (hli) | Rang ntawm qhov siab (hli) |

| 145-450 | 87-280 | 62-150 |

Tungsten carbide yob

Ntau yam ntawm cov cheeb tsam txheej txheem: 154-450mm

Ntau ntawm INRERE INCH: 87-280mm

Ntau ntawm qhov siab: 62-150mm

Cov lus ntawm kev qhia tshwj xeeb ntawm kev ua tiav yob

| Tev muaj kev pab rau OD, ID, thiab qhov siab ntawm yob ib ncig (hli) | ||||

| Ntaus | OD≤200 hli | Lwm> 200mm | ||

| Zoo dua qib | Kawm ib txwm muaj | Zoo dua qib | Kawm ib txwm muaj | |

| Kam rau od | ± 0.020 | ± 0.050 | ± 0.030 | ± 0.050 |

| Kam rau id | +0.020 | +0.035 | +0.025 | +0.050 |

| Kev kam rau h | ± 0.025 | ± 0.100 | ± 0.050 | ± 0.100 |

| Cov qhab nia tseem ceeb rau TC hlau foob lub nplhaib kho tshuab lub nplhaib nrog siab ntom ntom | ||||

| Teem nqi | Ntom ntom (g / cm³) | Hardness (HRA) | TS (MPA) | Daim Ntawv Thov Pom Zoo |

| Yg4c | 15 | 89.5 | 1800 | Mas siv cov khawm me me rau percusion cov khoom thiab raws li cov ntxig ntawm cov kev xav tau qeeb qeeb txiav cov mos mos, cov qauv tsim nyuaj. |

| YG6 | 15.8 | 89.5 | 1700 | Mas siv los ua cov nyees khawm ntawm cov me me thiab nruab nrab qhov loj me me thiab raws li cov ntxig ntawm cov kev cia siab rau cov mos muag muag los txiav cov mos muag, cov qauv sib zog. |

| Tsaus ntuj | 14.7 | 88.5 | 2300 | Mas siv los ua cov nyees khawm ntawm cov me me thiab nruab nrab qhov loj me me thiab raws li cov ntxig ntawm cov kev cia siab rau cov mos muag muag los txiav cov mos muag, cov qauv sib zog. |

| Yg13c | 14.3 | 86 | 2500 | Mas siv raws li cov ntxig thiab cov nyees khawm thiab cov pob tw ntawm cov pob tw qab zib. |

| YG15 | 14 | 86.5 | 2500 | Nws yog qhov muaj zog dua, thiab tsuas yog siv los ua cov ntxig thiab cov nyees khawm ntawm cov pob zeb-pentshis, hnyav |

Ntim & Xa Tawm