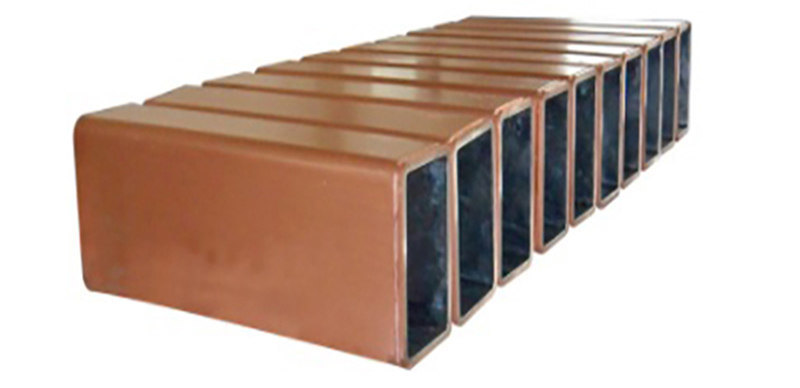

Cov ntaub ntawv ntawm tooj liab kheej hau yuav tsum yog cov uas muaj lub zog zoo, nkees ua lub zog, qis elongation, qis elongation thiab high cua kub cees. Raws li qhov tshwm sim, cov khoom xws li phosphorous deoxidize tooj liab (DHP), CUAG, CR-ZR-CU yog dav tau txais los ntawm txhua lub teb chaws. Cov nqaij nyuj: tooj liab muaj qis dua hardness uas ua rau qis qis tiv thaiv cov khoom muaj abrasive. Yog li no, thaj chaw ntawm qis dua ntawm cov pwm, qhov kev ntxhov siab ntau dua vim yog cov plhaub, yuav hnav ntau dua. Txhawm rau nce lub neej tooj liab lub sijhawm ntawm tooj liab pwm, sib xyaw pwm pwm sab hauv sab hauv sab hauv plating nrog cov hardness yog xav tau. Feem ntau ntawm cov tooj liab pwm rau me me loj billet cast casting tsis siv hauv kev casting system uas muaj txhav street cov nyiaj yug, yog li ntawd lawv muaj kev hnav ris tsho heev. Peb siv cov phiaj xwm nyuaj ua plating kom ua rau lub neej ntawm cov leeg ntoo. Lub plating thickness yuav tswj nyob rau hauv qhov zoo tshaj plaws. Raws li rau txheej ntawm tooj liab pwm, raws li peb xyoo kev paub, peb muaj peev xwm muab cov txheej txheem crating, ni-fe txheej ntawm ntau tus neeg muas zaub ob leeg hauv tsev thiab txawv teb chaws.

Lub Sijhawm Post: Dec-30-2022